In this project they included the Stl files to make the casing. I downloaded them and started printing. At the same time I ordered the electronics items on the Adafruit website with some other items I already planned to buy.

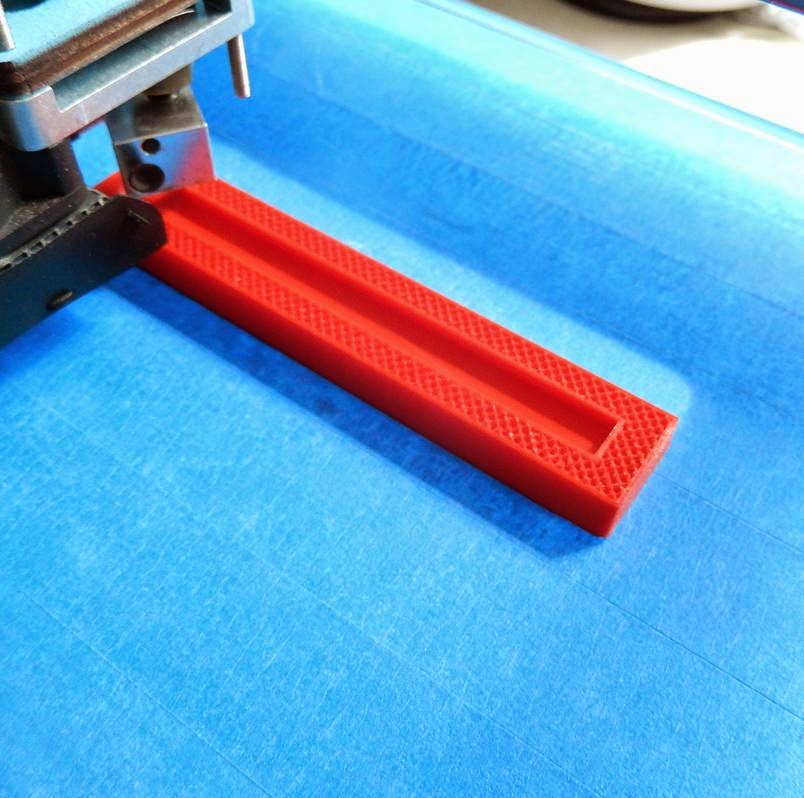

First the Tray for the pcb with the 16 buttons. This item took 46 minutes to print.

Then the Top part. This item printed in 1:56 hours.

The next print for the big part, the frame. I had to cancel it while it was printing. Cura keeps the last settings available for next prints. In it I had set the infill to zero. This way the case was build with walls which had no connection to each other.. This would lead to a very unstable frame. Here are images of these walls.

The printtime was already 1:46 hour but it would take at least 5 hours to finished...So better start a new print..

The frame started good but half way it started to go wrong. Underextrusion. I did let it finished and I am thinking about covering the underextruded parts with glue. Strangely after the part of the underextrusion the best part was printed..very smooth and without mistakes. But I also think about a new try.

The print of the frame took 5:25 hours.

After this print I started immediately to print the bottom part. And that one came out very good. Printing time was 2:17 hours.

The next day I wanted to have another go with the frame part. I started the print at 6:30 in the morning. So around 12:00 am it should be ready.

And it did. The frame came out very good. Without mistakes in extrusion. Printing time was 5:25 hours. Here is the frame.

And here is the full box. I am very glad it worked out fine.

The next thing will be to find the screws and wait for the Adafruit Trellis items to arrive.

Total printing time for the box was:

- Top 1:56

- Tray 0:46

- Frame 5:25

- Bottom 2:17

- Total 10:24 (the two mistakes added another 7:11)